Maker Nexus Move-In

July 8th, 2025

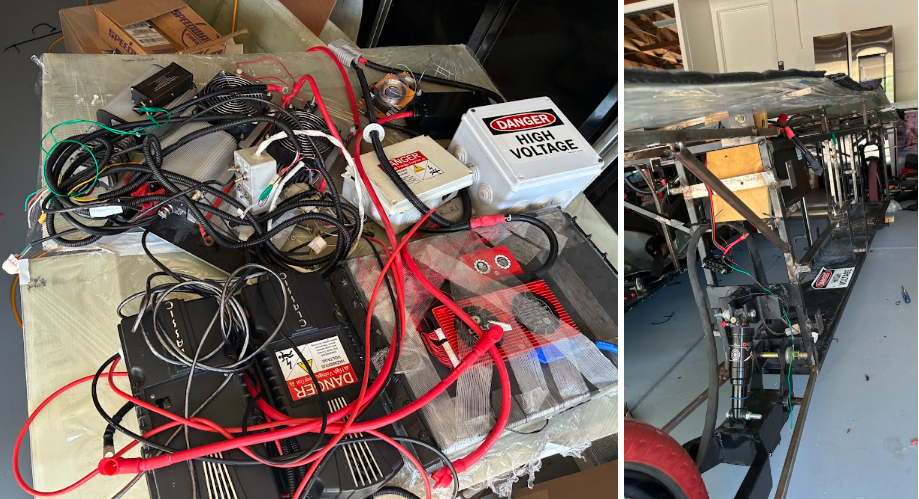

As school ended in May (along with AP exams and finals), we were able to get started with the move to Maker Nexus, the Sunnyvale-based makerspace where we do our metalwork and welding. This was a process that began with cleaning up the car—welding and cutting create a lot of sparks that could damage delicate wires, so we removed the entire electrical system. Over several days’ meetings, we cut wires and unplugged connections until the MPPTs, battery and battery box, auxiliary battery, relays, shunts, lights, and a lot more were disconnected. We also removed the giant set of solar panels, now stored in Anish’s garage for safekeeping, as well as some other flammable materials on the car—the foam padding, water bottle, fire extinguisher, etc.

The removed electrical components and the mostly empty side of the car.

After moving the car to Maker Nexus and into our new designated storage space, the older members were able to start some metalwork. The newer members had to first take metal shop classes and learn to use tools like the chopsaw, bandsaw, angle grinder; they then had to take a welding class and get in their required hours of practice. We’re super grateful to Maker Nexus for accommodating our project for the third year in a row, and to metal shop manager Ginger LaVelle for working out our contract and making sure everything goes well.

Over the course of the past several weeks, we’ve been meeting three times a week to work on the car. We’ve removed all of the metal parts that had been welded last-minute during the previous season, since the welds had been done with the portable welder and were too weak to be reliable (some didn’t even need angle grinding and could be hammered straight off). These parts included metal bars meant to hold up the composite shell in the rear, on the sides, and in the front of the car; as well as bars that held the solar panels up. After that came quite a bit of grinding down of hazardous sharp edges. We recently also cut apart the two compartments—electrical and driver—and rewelded them to be closer together. This allowed room for a crush zone to be attached to the electrical compartment to protect the battery in case of a crash, thus solving an issue with the rules that we encountered in last year’s scrutineering.

Diana and Anish welding the two compartments back together.

Last week, we received the front suspension parts we’d ordered: Harley Davidson wheels, axles, and go-kart dampers. With these shiny new items, in addition to the new steel we’d bought, we were able to get started building our home-made suspension. After some more cutting, drilling, angle grinding, and welding, we’ll be able to test! The next steps will be to work on steering, rear suspension, and brakes. Overall, our team’s been working steadily, settling into a working routine. Our choice to race next year instead of this year has allowed us to take a fun and relaxed pace instead of the panicky rush of previous summers. We’re happy to be making a little progress each day. The teams at the Solar Car Challenge this year are a few days away from racing, so best of luck to them!